Road Paving Solution - CEMEX UAE ReadyMix

Road Paving Solution

What is Paverex RCC?

- Paverex Roller Compacted Concrete is a zero-slump concrete with compressive strength greater than 40N/mm2

- Placed with asphalt pavers to form a non reinforced, concrete pavement.

- Successfully and economically combines strength and durability with ease of construction.

Characteristics

- Very innovative solution.

- Short construction time.

- Surface finish not as smooth as conventional concrete.

Application

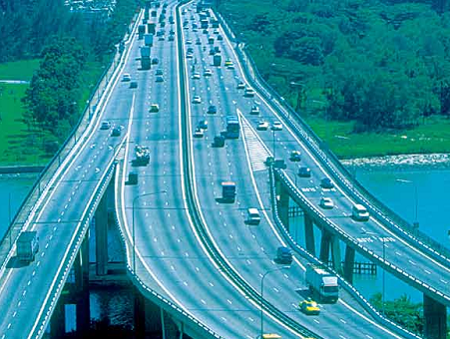

- Road Highways

- Local Streets

- Parking Lots

- Industrial Floors

- Airport Runways and Apron

- Rural Roads

- Base for Roads

RCC Construction Process

Sustainability Benefits

Environmental

Less Fuel Consumption

Less Fuel Consumption

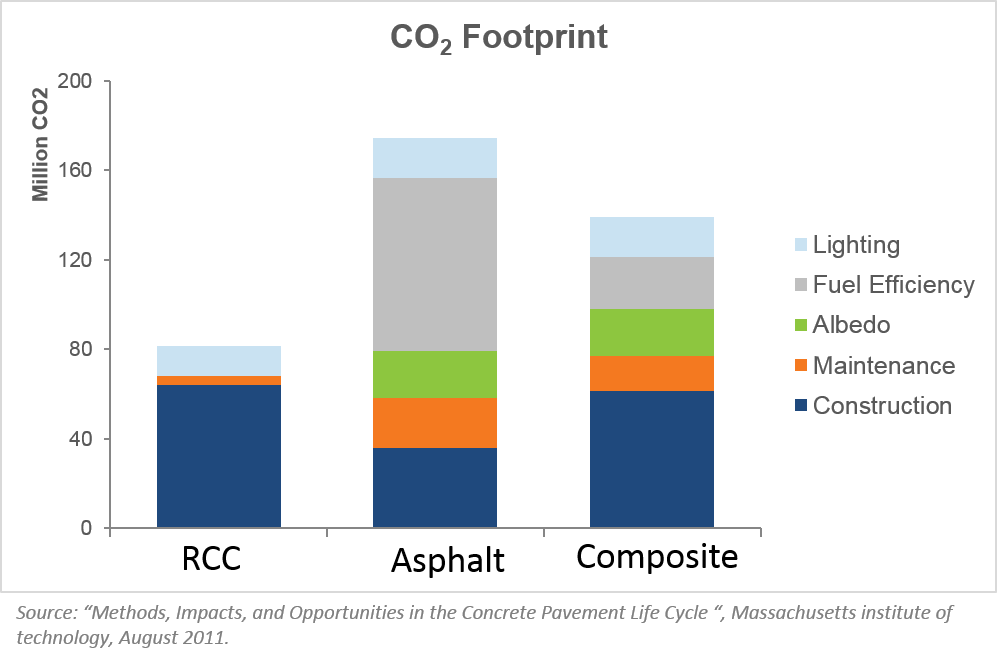

XReducing CO2 Footprint

Reducing CO2 Footprint

XRCC paving reduces footprint because of its technology that brings better quality and more durability to the final product.

The usage of eco-friendly raw materials also contributes to the reduction of CO2 emissions.

30% reductions on CO2 due to GGBS Integration.

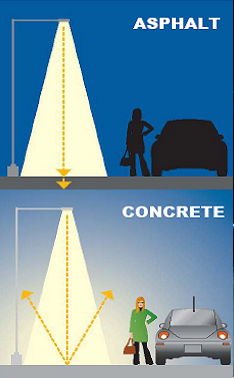

Less Energy Consumption

Less Energy Consumption

XConcrete paving improves night time visibility and because of its reflective nature, a specified luminance level can be achieved with fewer lighting fixtures and standards. Ultimately, translating to lower costs and lower energy consumption over time.

Source: Green Highways: Environmentally and Economically Sustainable Concrete Pavements, American Concrete Pavement Association

37% less street public lighting energy consumption

as concrete surfaces reflect 5x more than asphalt.

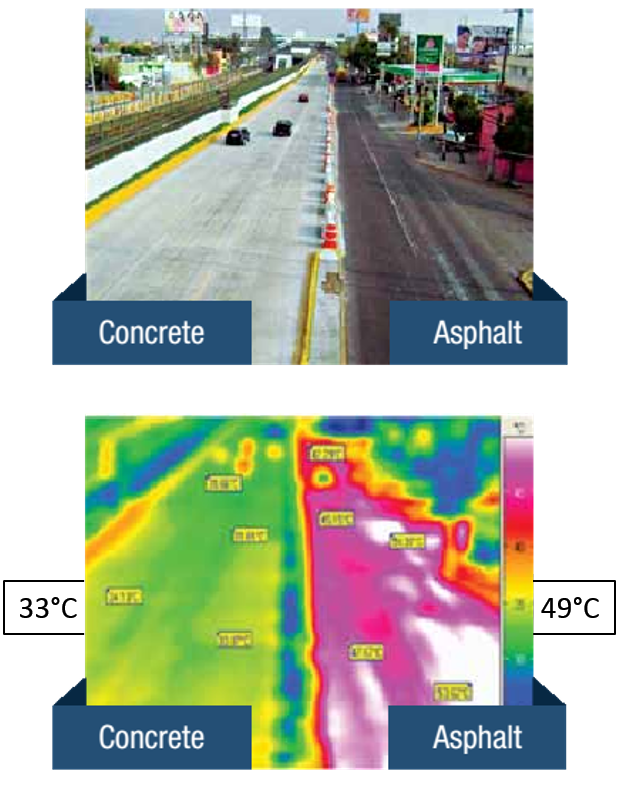

Cooler Surfaces

Cooler Surfaces

XCities are warmer than their surroundings, which in summer leads to discomfort, medical conditions, and higher air conditioning use.

Light-colored surfaces such as concrete reduce this so-called Urban Heat Island Effect.

33% Cooler RCC vs Asphalt surfaces or up to 15°C reduction.

Thus, reducing the Heat Island Effect.

Local Raw Materials

Local Raw Materials

X

Social

Better Night Visibility

Better Night Visibility

XPossibility to use contrasted pigmentation in concrete mix (lane – shoulders)

Increased viewing distance

Lower risk of damage to pedestrians – better and earlier detection by driver

5x more light reflection than asphalt paving

making road safer for pedestrians and road users.

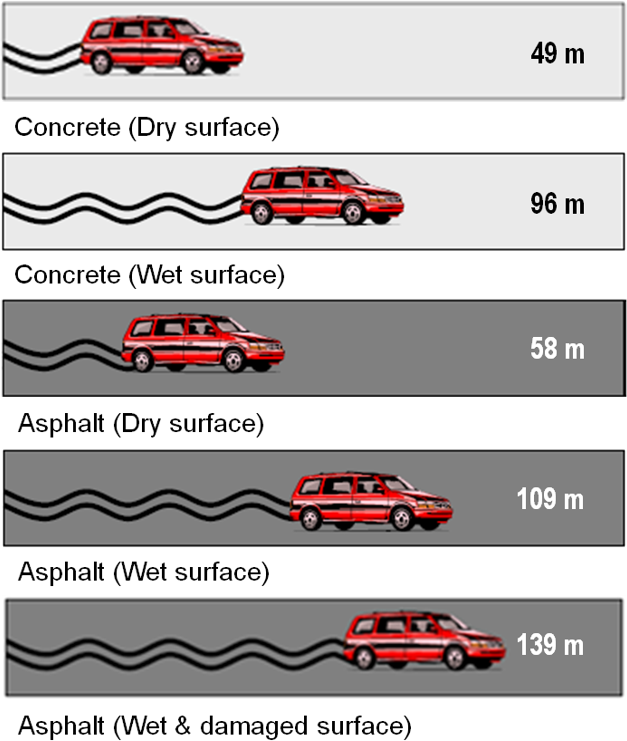

Shorter Braking Distance

Shorter Braking Distance

XAs concrete surfaces are very stable the advantage versus asphalt increases over time.

In addition, as concrete pavements do not rut, the risk of hydroplaning is effectively eliminated.

It improves traction reducing the braking distance and gives non-skid surface.

Up to 30% Reduction of breaking distance

that reduces accidents on the roads.

Tire Protection

Tire Protection

XRCC creates cooler environments that translates to cooler tire temperatures. This effect reduces the tire blowout and the accidents derived from them.

Significant reduction in tire blowouts due to LOWER temperature.

Healthier Working Conditions

Healthier Working Conditions

XLess Traffic Disruptions

Less Traffic Disruptions

XReduced frequency and time spent on maintenance activities leading to

Better road surface quality of RCC roads means constant driving speeds are maintained throughout the network.

30 years to first major rehabilitation vs asphalt of just 15 years.

Economic

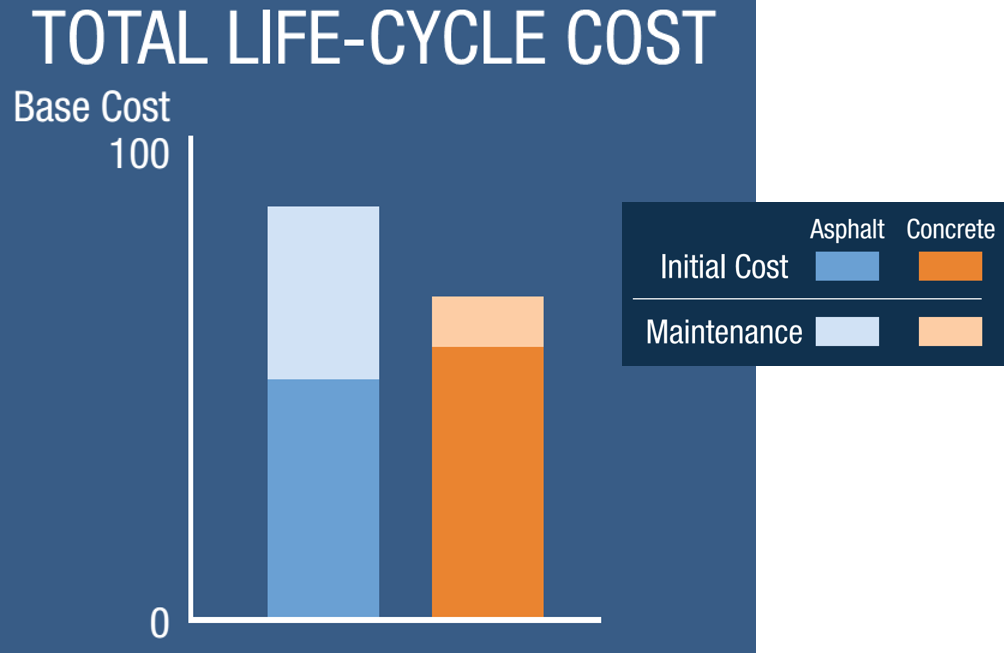

Lower Life Cycle Cost

Lower Life Cycle Cost

XIncluding the full life cycle of the project, concrete has significant lower total cost versus asphalt despite its slightly higher initial cost.

*New construction 6” RCC/8” STAB. SG VS 2” HMAC/10GRAN. BASE/8” STAB. SG.

10-30%* total lower life-cycle costs over 30-50 year period.

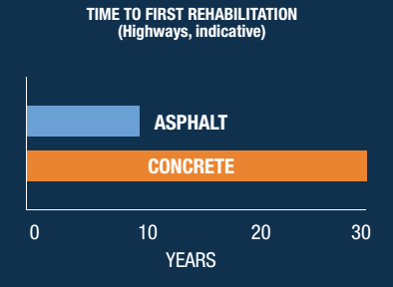

Increased Durability

Increased Durability

XRCC paving has a longer useful life while asphalt needs its first rehabilitation within 10-15 years. RCC will usually last 25-30 years without major rehabilitation.

The superior durability of concrete over asphalt ensures low and predictable maintenance costs.

3x more service life than asphalt paving before major rehabilitation.

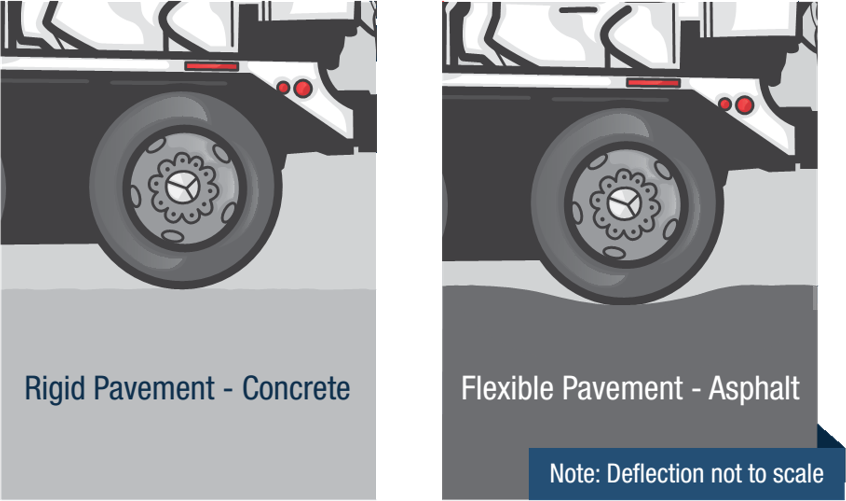

Fuel Savings

Fuel Savings

XOn the rigid surface of a concrete pavement the wheels do not sink in as much as they do on flexible, i.e. asphalt pavements.

This effect, called deflection, is invisible to the naked eye, but has a noticeable impact on fuel efficiency.

up to 5% savings on fuel consumptions by using RCC pavements.

Supporting Local Industry

Supporting Local Industry

XSupporting the local industry will lessen the need to import bitumen as it represent 30% of the raw material of asphalt.

RCC generates increased demand for jobs and promotes the economic health of the country.

1,000 MT estimated additional demand of Cementitious

per each 1 km of RCC paving.

Lighting Requirement Reduction