Product Polypropylene Fibre Concrete - Product Polypropylene Fibre Concrete - CEMEX UAE ReadyMix

Products Menu

Cement Bag

CEMEX Shotcrete

Decorative Concrete Pavements

Durable Concrete

Evolution®

Expanded Polystyrene Panels (EPS) + CEMEX Shotcrete

Foamed Concrete

Insulated Concrete Forms (ICF) + Evolution®

Lightweight Concrete

Paverex (Roller Compacted Concrete)

Plaster

Polypropylene Fibre Concrete

Promptis®

Readybase

Readyfill

Readyscreed

Steel Fibre Concrete

Vertua®

Waterproof Concrete

Product Description

Polypropylene fibre (short-cut strands of very fine denier monofilament*) is added to the concrete during batching. Thousands of individual fibres are then evenly dispersed throughout the concrete during the mixing process creating a matrix-like structure.

Properties

- Improves concrete’s resistance to plastic shrinkage cracking.

- Inhibits formation of micro-cracks due to dimensional change.

- Reduces sedimentation.

- Increased cohesion of the mix.

- No requirement for crack control steel mesh.

- Concrete placement and crack control in ONE operation.

- Reduced bleeding.

- Less expensive (per m2) than conventional steel mesh reinforcement.

- Reduced plastic cracking means a reduction in surface permeability.

- Bleed water control inhibits migration of cement fines and sand to the surface.

- Even distribution of fibres throughout the concrete.

- A tougher surface with fewer bleed hole.

- Reduced plastic cracking means a reduction in surface permeability.

- Bleed water control inhibits migration of cement fines and sand to the surface.

- Even distribution of fibres throughout the concrete.

- A tougher surface with fewer bleed holes.

Benefits

- Reduced frequency of plastic cracking.

- Improved durability and reduced permeability.

- Decreases risk of plastic settlement cracking over re-bar.

- Reduced settlement and easier finishing.

- No delays to fast track schedule.

- Easier positioning of joints.

- No need to purchase and store additional material.

- Reduced site labour requirement.

- No secondary steel mesh is required and reinforcement is automatically positioned.

- Easier finishing of the concrete surface.

- Reduced project costs.

- Enhanced durability.

- Harder, more durable surface with better abrasion resistance.

- Improved flexural properties.

- Increased resistance to spalling at higher temperatures and so…. better fire resistance.

- Reduced absorption of water, chemicals and dirt.

Application

- Most small builder, cash sales and DIY applications

- Internal floor-slabs (retail stores, warehouses, etc.)

- External slabs (driveways, yards, etc.)

- Agricultural applications

- Roads, pavements, driveways, Kerbs

- Shotcrete; thin section walling

- Overlays, patch repair

- Water retaining structures, marine applications

- Security applications such as safes and strong rooms

- Deep lift walls

Technical Data

| Concrete Grade (N/mm2) | 30 to 80 |

| Durability (RCP, WP, WA) | 800 to 4000, 10 to 20mm, 1.0 to 3.0 |

| Workability Slump (mm) | 75 to 200 |

| Workability Retention (Hours) | 1 to 3 |

| Maximum Aggregate Size (mm) | 10 or 20 |

| Typical Density (Kg/m3) | 2,450 |

| Cement Types | OPC, SRC, MSRPC |

| Supplementary Cementitious Materials | GGBS / Micro silica, PFA |

How to use

- The concrete can be compacted and finished normally. Trowelling embeds the fiber in the concrete surface.

- Some fibers may be exposed where textured finish is applied, but these quickly disappear.

- Batching fiber reinforced concrete - longer batch times.

- Concrete with fiber can be pumped in most cases.

- Control joints are necessary and should be spaced at normal intervals prescribed for an reinforced slab design.

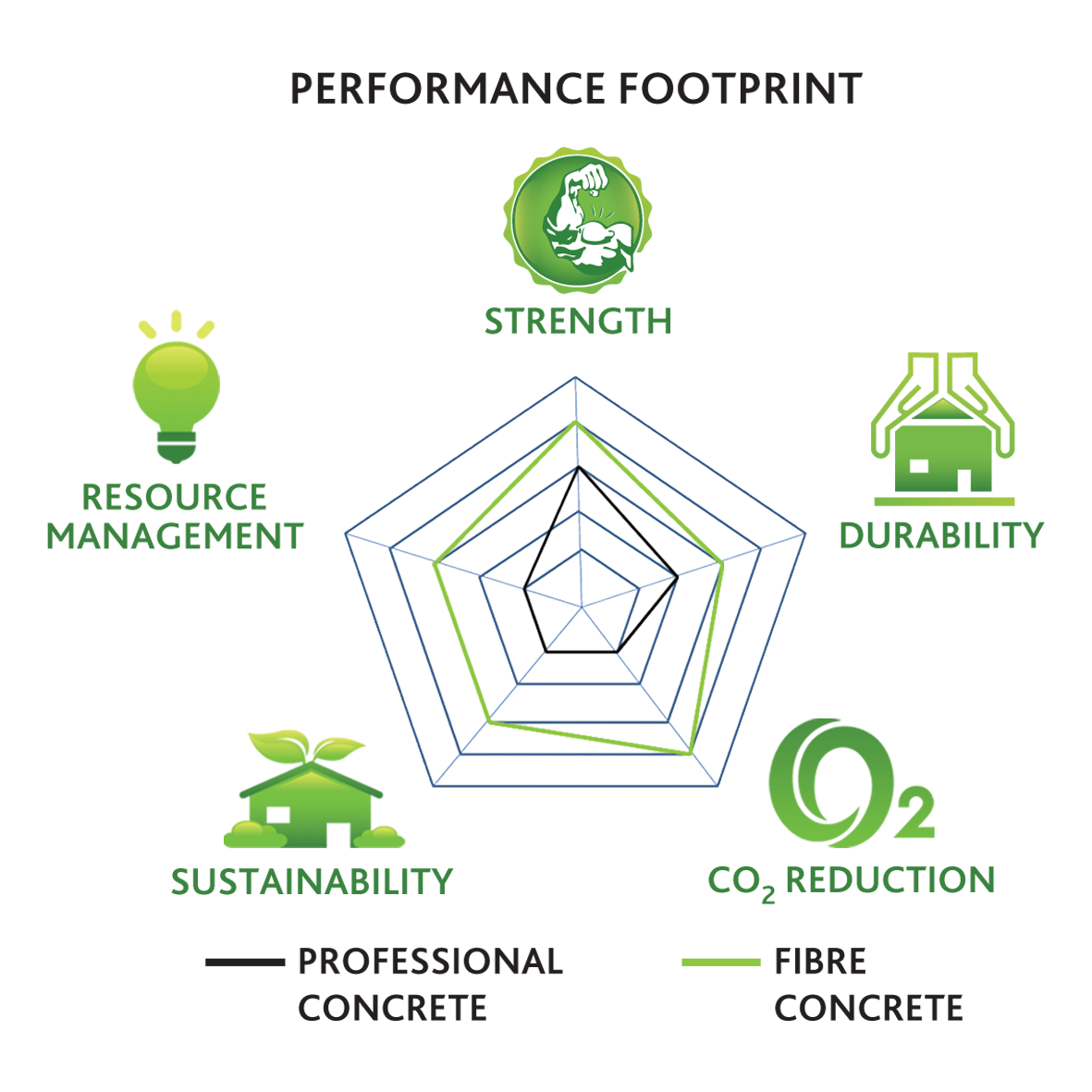

Performance footprint

.png)

You have questions?

If you have questions, please contact our Product Specialist.

To download

Fibre Concrete Brochure.pdf

Download /documents/17829785/22688682/Fibre+Concrete+Brochure.pdf/74a571c3-acbc-0fab-3707-e2b910049f14?t=1502710157327Polypropylene Fibre Concrete Data Sheet.pdf

Download /documents/17829785/22688682/Polypropylene+Fibre+Concrete+Data+Sheet.pdf/113fd691-bcf0-e31c-5bee-03b5cdd3470b?t=1502353846035Worth reading

Nothing more to read.

Go to top of page