Product Steel Fibre Concrete - Product Steel Fibre Concrete - CEMEX UAE ReadyMix

Products Menu

Cement Bag

CEMEX Shotcrete

Decorative Concrete Pavements

Durable Concrete

Evolution®

Expanded Polystyrene Panels (EPS) + CEMEX Shotcrete

Foamed Concrete

Insulated Concrete Forms (ICF) + Evolution®

Lightweight Concrete

Paverex (Roller Compacted Concrete)

Plaster

Polypropylene Fibre Concrete

Promptis®

Readybase

Readyfill

Readyscreed

Steel Fibre Concrete

Vertua®

Waterproof Concrete

Product Description

Steel Fibre Concrete utilises steel fibres designed to provide ultimate performance under intense loading conditions. This fibre system provides superior resistance to cracking in hardened state concrete, as well as maximum resistance to damage from heavy impact and dynamic loading.

Properties

- Increase flexural toughness / residual strength

- Provides post-crack performance

- Improves plastic properties of concrete

- Increased impact and abrasion resistance

- No requirement for crack control steel mesh

- Concrete placement and crack control in ONE operation

- Cost effective alternative to conventional steel mesh reinforcement

- Controls cracking which occurs in the hardened state

- Even distribution of fibres throughout the concrete

- A tougher surface with fewer bleed holes

Benefits

- Increased load bearing capacity of concrete

- Potential reduction of concrete slab depth

- Concrete retains load carrying capability after cracking has occurred

- Increased durability and reduced maintenance costs

- No need to purchase and store additional material

- No delays to fast track schedule

- Easier positioning of joints

- Reduced site labour requirement for on-site handling and cutting of steel reinforcement

- No secondary steel mesh is required and reinforcement is automatically positioned

- Reduced project costs

- Enhanced load bearing capability

- Improved flexural properties

- Reduced absorption of water, chemicals etc.

Application

- Heavy duty flooring applications – internal & external

- Civil Engineering applications

- Elevated composite metal decks, bridge decks, mass foundations

- Jointless industrial floors

- Overlay, patch repairs

- Walls

- Conventional rebar replacement

Technical Data

| Concrete Grade (N/mm2) | 30 to 80 |

| Durability (RCP, WP, WA) | 800 to 4000, 10 to 20mm, 1.0 to 3.0 |

| Workability Slump (mm) | 75 to 200 |

| Workability Retention (Hours) | 1 to 3 |

| Maximum Aggregate Size (mm) | 10 or 20 |

| Typical Density (Kg/m3) | 2,450 |

| Cement Types | OPC, SRC, MSRPC |

| Supplementary Cementitious Materials | GGBS / Micro silica, PFA |

How to use

- The concrete can be compacted and finished normally.

- Troweling embeds the fiber into the concrete surface.

- Concrete with fiber can be pumped in most cases, but some mix design adjustments may be necessary.

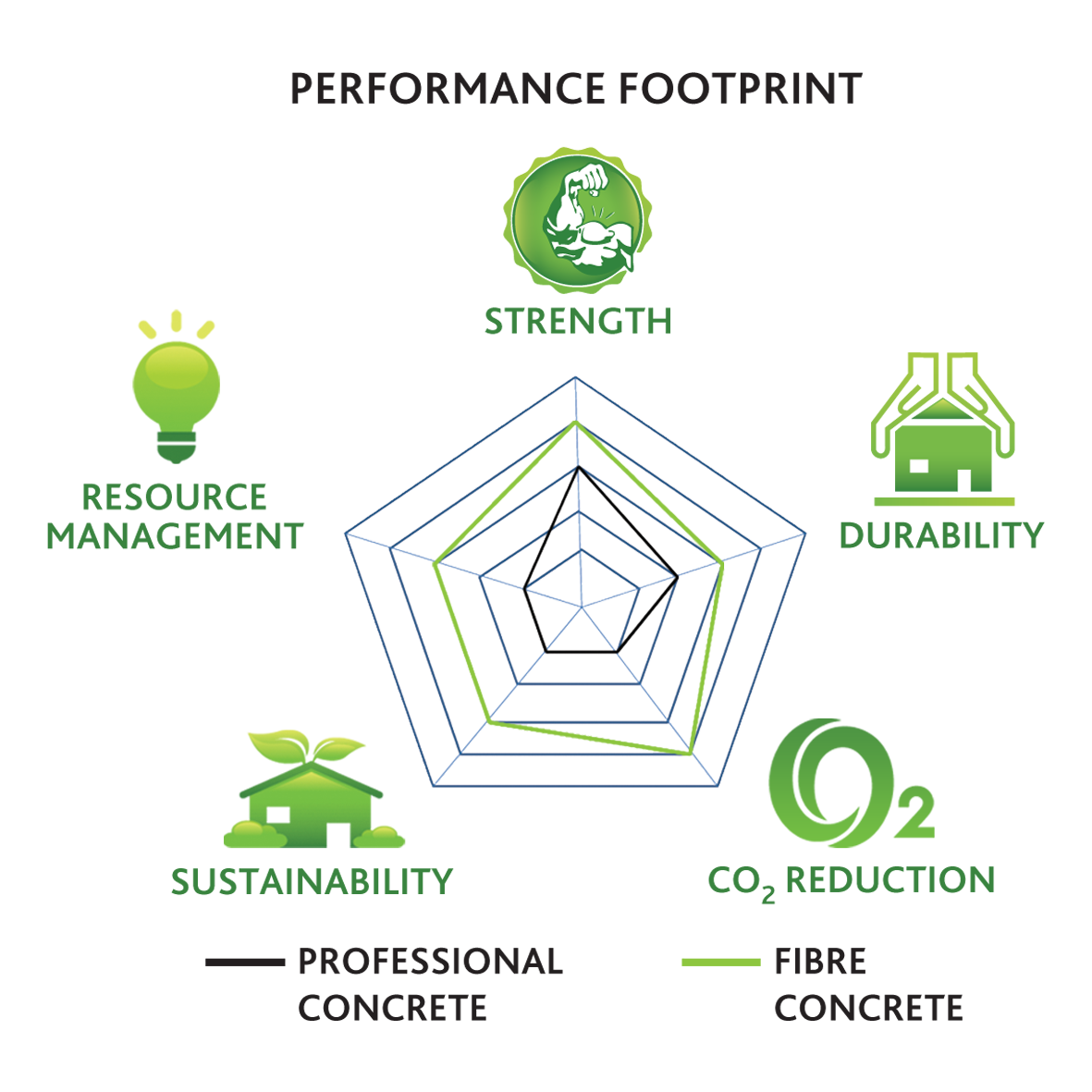

Performance footprint

You have questions?

If you have questions, please contact our Product Specialist.

To download

Fibre Concrete Brochure.pdf

Download /documents/17829785/22688682/Fibre+Concrete+Brochure.pdf/74a571c3-acbc-0fab-3707-e2b910049f14?t=1502710157327Steel Fibre Concrete Data Sheet.pdf

Download /documents/17829785/22688682/Steel+Fibre+Concrete+Data+Sheet.pdf/8ee61ada-a98a-cdf1-700c-7757b6eb4e27?t=1502353888570Worth reading

Nothing more to read.

Go to top of page