Product CEMEX Shotcrete - Product CEMEX Shotcrete - CEMEX UAE ReadyMix

Products Menu

Cement Bag

CEMEX Shotcrete

Decorative Concrete Pavements

Durable Concrete

Evolution®

Expanded Polystyrene Panels (EPS) + CEMEX Shotcrete

Foamed Concrete

Insulated Concrete Forms (ICF) + Evolution®

Lightweight Concrete

Paverex (Roller Compacted Concrete)

Plaster

Polypropylene Fibre Concrete

Promptis®

Readybase

Readyfill

Readyscreed

Steel Fibre Concrete

Vertua®

Waterproof Concrete

Product Description

CEMEX Shotcrete is a specially designed concrete developed for use with compressed air spraying equipment. Shotcrete is a fast and effective way to apply concrete in areas where using conventional concrete would be difficult. CEMEX Shotcrete also forms an integral part of an innovative low cost, low carbon housing solution.

Properties

- Rapid construction method

- Can be applied in any shape

- Elimination of formwork

Benefits

- Savings in time and labour

- Reduction in wastage

- Can make shapes that are hard to achieve with conventional concrete

- Reduced cost from elimination of formwork

- Storage area not required for formwork

- Craneage not required for formwork

Application

- Swimming Pools

- Domes

- Skateparks

- Repairs of damaged concrete surfaces such as walls and structural members such as beams, columns and connections

- Tunneling

- Rock and slope stabilization

Technical Data

| Concrete Grade (N/mm2) | 5 to 40 |

| Durability (RCP, WP, WA) | Not required |

| Workability Slump (mm) | 75 to 200 |

| Workability Retention (Hours) | 2 to 8 |

| Maximum Aggregate Size (mm) | 5 or 10 |

| Typical Hardened Density (Kg/m3) | 2300 |

| Cement Types | OPC |

| Supplementary Cementitious Materials | Duracem ® |

| Colours | Grey |

How to use

- Two different processes are used, either the wet process or the dry process.

- In the wet process, all the concrete constituents are batched and mixed together before being fed into a pump. The mixed concrete is conveyed under pressure to the nozzle where compressed air is injected, shooting the concrete into position.

- In the dry process, only the dry ingredients are batched together and pumped under pressure to the nozzle. Pressurized water is introduced at the nozzle, which, along with the force from the pump, projects the concrete into the area being repaired. The addition of water is therefore under the control of the nozzle operator in the dry mix process and the end product tends to be more variable.

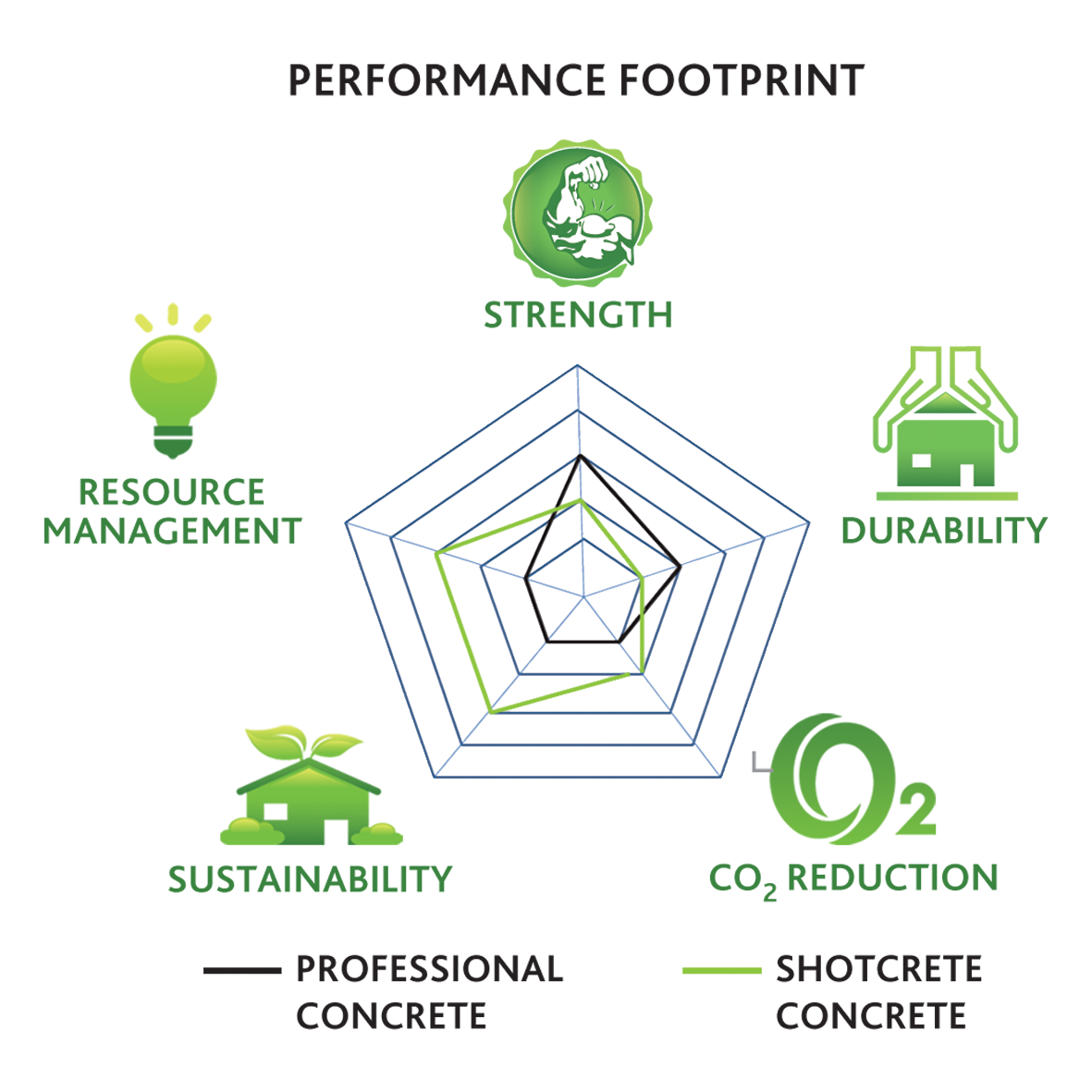

Performance footprint

You have questions?

If you have questions, please contact our Product Specialist.

Worth reading

Nothing more to read.

Go to top of page